Growth

Electrifying City Bus Fleets in Europe

Groeneveld-BEKA’s auto-lubrication systems play an essential role

In 2021, the European Union announced that sales of new cars and vans producing carbon emissions would be banned by 2035. They also raised the target for reducing CO2 emissions to 55% by 2030 — up from 37.5%.

The announcement followed four years of effort by European cities to significantly reduce emissions from public transportation. In 2017, 50 cities signed the “Clean Bus Deployment” initiative, promoting the large-scale deployment of emissions-free buses.

Groeneveld-BEKA, a Timken-owned business, works with bus manufacturers throughout Europe to provide automatic lubrication (AL) systems that help extend operating life, further reduce the need for petroleum products, and reduce waste and maintenance costs.

“A Groeneveld-BEKA® automatic lubrication system with an air-sealed pump filled with biodegradable grease contributes significantly to the sustainability of a vehicle.”

Michal Zagozda

senior sales representative for Groeneveld-BEKA

Supporting Europe’s green fleets

“Electric buses resemble internal combustion engine (ICE) buses in some ways,” says Michal Zagozda, senior sales representative for Groeneveld-BEKA. “They still require lubrication. They also hold about the same number of people, so transportation departments still need to maintain large fleets to serve their citizens.”

Groeneveld-BEKA’s automatic lubrication systems reduce the labor required to maintain buses, and they do it without removing them from service. Computer-controlled oil management also reduces errors significantly, compared to human-dependent administration, which helps keep buses running longer without breaking down as often.

Automatic lubrication systems, whether they’re attached to diesel trucks or electric buses, also provide environmental benefits. “Because they deliver the exact amount of grease that the vehicle needs, they can reduce grease consumption by up to 80%,” says Zagozda. “A Groeneveld-BEKA® automatic lubrication system with an air-sealed pump filled with biodegradable grease contributes significantly to the sustainability of a vehicle.”

AL is especially important for electric buses, however, because their batteries make them much heavier than ICE buses. “EVs sustain more wear on pins and bushings,” says Zagozda. Electric buses also tend to be sold with longer repair and maintenance contracts, which incentivizes manufacturers to integrate maintenance systems into the vehicle.

Collaborating with the best in the business

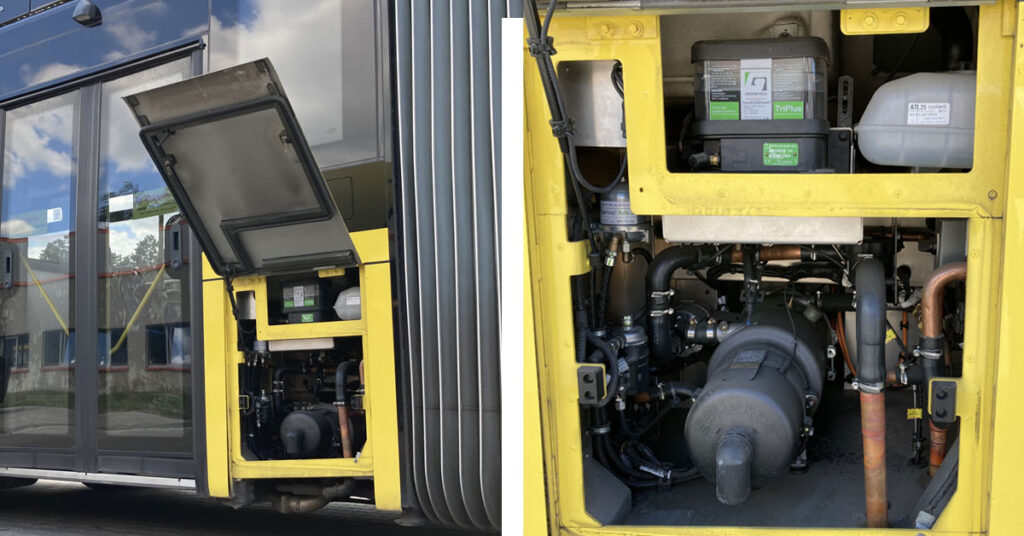

Because AL systems are installed at the factory today, rather than as aftermarket add-ons, they’re completely integrated into each bus. Groeneveld-BEKA engineers work closely with manufacturers and operators to use space optimally and connect controls into the bus’s electronics.

“Our systems have been developed over many years of collaboration with the bus industry,” says Zagozda. “The new generation of the Oilmaster — 3.1 with the tilt sensor — was designed to eliminate the risk of refilling the engine with oil while a bus is tilted.”

“Likewise,” he says, “the TriPlus pump, one of our most successful products is used on articulated buses. It lubricates the front articulating joint and axle separately, in independent doses.”

While electric buses are having an impact on emissions in Europe, hydrogen-propelled buses are also making headway. “Last year, we supplied hydrogen buses with undercarriage lubrication to a bus operator in the Netherlands,” says Zagozda. “This year we’ll deliver more to Cologne, Germany and to Wuppertal, as well as to Konin, in Poland.”

“Electricity and hydrogen propulsion are the future,” he says.

Five storage tanks power this hydrogen-fuel-cell bus.

Bus fleets all over the world are transitioning to electric, and Rollon by Timken is also contributing technology to the cause. Find out how Rollon telescopic rails are simplifying battery maintenance, recharging and replacement.

Last Updated: 2023/09/22

Published: 2022/08/14