Talent

Lagersmit Service Engineering: Where Technical Know-How Meets Adventure

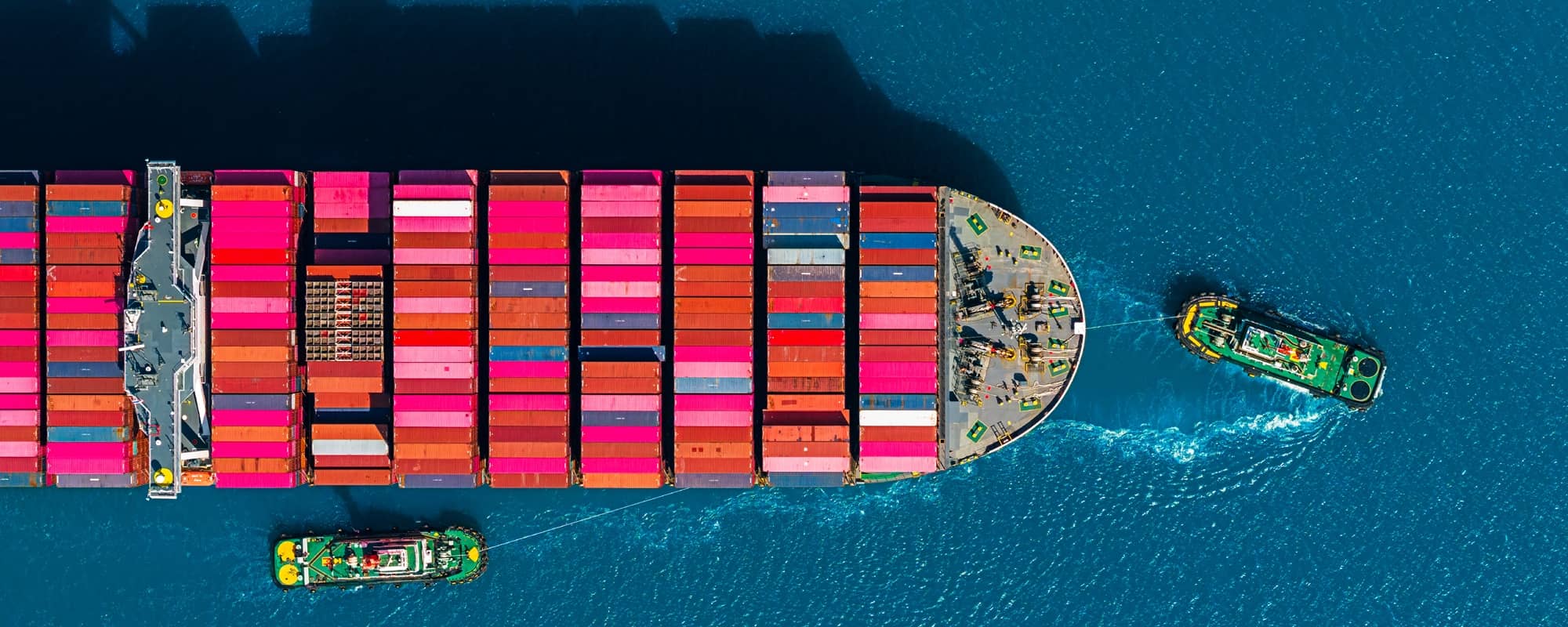

Ruud Habing’s marine service engineering journey began in the classroom, studying naval architecture in the Netherlands. At a young age, Mahmoud Chebbo accompanied his father to the family’s drydock business. And Maurice Zwaneveld gained early experience at two Netherlands-based dredging companies. Despite their varied backgrounds, they all combine technical precision and real-world adventure to help Lagersmit — part of the Timken Industrial Motion portfolio — return some of the world’s largest seagoing vessels to work.

Lagersmit, which specializes in rotating shaft sealing solutions for stern tubes, thrusters and bulkheads in commercial and industrial workboats, joined Timken in 2023 with a 170-year legacy of marine expertise and service. Today, its growing service engineering team solves tough marine challenges onsite and on the spot — often deploying globally within 24 hours and not knowing exactly what needs solved until they get on location.

“Our team overcomes some very big challenges to keep ships and global trade moving.” says Ruud Habing, who began his career as a Lagersmit research and development engineer and currently serves as the company’s service manager. “It’s part of our promise to deliver peace of mind with our best-in-class products and services.”

World-class problem solving

Lagersmit’s core team of service engineers and coordinators work from the Netherlands and strategic hubs in major port cities including Rotterdam, Shanghai and Singapore. Every job demands precision, adaptability and a deep understanding of Lagersmit seals and their role in marine propulsion systems.

For example, cargo vessel operator recently called for assistance. In dry dock, the operator’s maintenance team had completed repair work on the propulsion shaft sealing system. The parts didn’t fit upon reinstallation. At risk: missing the ship’s deadline to sail within the week and resulting in possible contract breach and off-hire losses.

Lagersmit service engineers quickly responded, taking measurements that confirmed inaccuracies in the ship’s existing engineering drawings. The team coordinated rapid production of new Lagersmit components at its headquarters in the Netherlands and hand-delivered them within 48 hours. The ship sailed on schedule.

“One of our service engineers flew with the parts in his luggage,” said Habing. “We do whatever it takes.”

Careers built on innovation and technical curiosity

Mechanical problems are at the core of most Lagersmit service calls. Effective service engineers must understand the technical inner workings of entire systems — and have the practical know-how to conduct manual system repairs and upgrades.

Before leading Lagersmit’s service engineering team, Habing helped develop a sustainable, self-regulating sealing solution that helps eliminate oil emissions for seagoing vessels. As a service engineer, he installed and retrofitted the solution onto many ships and trained his colleages to do so as well. Today, more than 1,000 ships are outfitted with the environmentally responsible system.

Mahmoud Chebbo, service engineer, noted that the sustainable solution is one of his favorites to work with due to its high level of complexity and advanced engineering. It makes his work, he says, “more challenging and rewarding.”

He added: “What drew me to the marine industry is the incredible technology behind it. I worked with many propulsion systems and encountered Lagersmit seals in the field early in my career. They always impressed me, especially how well they were packaged and prepared. That attention to detail told me a lot about the company.”

Chebbo officially joined Lagersmit in 2021 after decades of hands-on marine field experience. He now represents the kind of seasoned professional that new service engineers shadow and learn from. His stories are extraordinary — from improvising seal system retrofits on ships with blocked equipment to adventurous travel to and from remote job locations.

Here’s a behind-the-scenes look at Chebbo’s work:

Built, not bought: the next generation of marine service engineers

Lagersmit doesn’t just hire marine service engineers — they cultivate them. New team members often come from the skilled trades with experience in welding, plumbing or maintenance on ships or in industrial settings. Some, like Chebbo, attended technical school. Yet there’s no formal school for what Lagersmit service engineers do. Instead, the company invests in real-world training, pairing young talent with veterans for on-the-job learning through real-world experiences.

When Maurice Zwaneveld, completed his training as a new Lagersmit service engineer, he shadowed several different colleagues on diverse customer projects in the Netherlands and around the world. He recalls an especially challenging job in South Korea, where ship access was difficult and time was short to make repairs. The experiences helped him gain broad insights, sealing application expertise and a solutions-oriented mindset.

“It prepared me to work independently,” added Zwaneveld, who joined Lagersmit after graduating from Seaman School in Rotterdam and working at two Netherlands-based dredging companies.

Beyond technical knowledge, new service engineers also learn how to treat customers — the Lagersmit way. Zwaneveld noted that’s what sets the company apart from others in the field.

“Beyond solving problems, it’s our job to prevent them,” he said. “We think proactively, communicate clearly and truly invest in building relationships. That makes all the difference to our customers.”

Across the Timken portfolio, service engineers solve customer problems and often are the first to identify emerging industry trends that lead to new product innovation. Meet more service engineers adding value for customers from industrial equipment operators to commercial aviation.

Last Updated: 2025/09/3

Published: 2025/08/15