Leadership

Timken and GGB: Exponential Expertise and Innovation

Timken has completed 24 acquisitions since 2010 to advance its engineered bearings and industrial motion expertise. The latest, GGB, provides additional technical solutions that strengthen Timken’s position in key strategic markets.

At GGB, engineers apply specialized knowledge in material science and tribology to innovate polymer coatings and plain bearing solutions for industrial applications, including pumps and compressors, HVAC, off-highway, energy, material handling and aerospace. With its acquisition of GGB, Timken diversifies its technical expertise and global leadership in highly engineered bearings — giving customers access to more custom bearing solutions across more markets.

GGB innovates and customizes polymer coatings and plain bearing solutions for applications like pumps and compressors, HVAC, off-highway, automotive, energy, material handling and aerospace.

Exponential innovation for shifting design trends

Andreas Roellgen, executive vice president and president of the Engineered Bearings group, said the GGB acquisition builds on Timken’s “advanced coating technologies and customized solutions for customers’ specific needs in fragmented markets”. While every acquisition is about adding value for customers, the more synergies there are, the greater the potential.

“Timken has very strong capabilities in material science, surface engineering and tribology — specific to steel-made bearings with rolling elements,” said Roellgen. “GGB builds on strengthening knowledge beyond steel-bearing competencies in all three areas that help address emerging technical trends for our customers.”

Two such trends are light-weighting and downsizing in applications like electric vehicles and wind energy. GGB plain bearing solutions help with this by using a wide range of materials like polymer coatings, engineered plastics, fiber-reinforced composites and bimetals.

In many cases, the two companies engineer adjacent, ultra-high-performance solutions for the same customers and equipment.

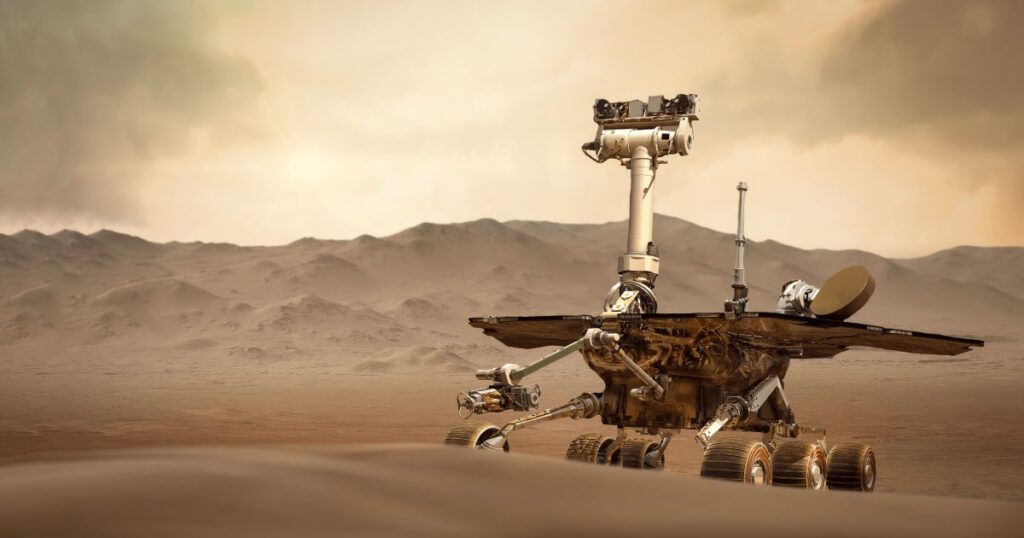

For example, the Curiosity rover has been operating on Mars for 10+ years and depends on GGB self-lubricating metal-polymer bushings to help drill for rock samples. Also onboard are two ¼ inch (6.35 mm) Timken bearings that run a vacuum pump in support of the rover’s analytical equipment. Essentially, GGB helps gather the samples, and Timken makes it possible to learn about them. Both are crucial to mission success.

Both Timken & GGB support the Curiosity rover that has been exploring Mars for more than a decade.

Shared legacy, complementary products

GGB was founded in 1899, the same year Timken began producing its first patented tapered roller bearing. Also similar to Timken, GGB demonstrated early leadership in key markets, inventing the first self-lubricated metal-polymer bearing, and they are recognized for their excellence in application engineering.

Chris Small, president, GGB, added that this is what sets GGB apart in the global plain bearings market.

“It’s extremely competitive, but we’re able to win customers because our strong application engineering capabilities and our legacy of material science innovations,” he said. “Collaborating with customers, designing into their applications and solving their most critical problems brings so much loyalty.”

And like Timken, GGB has a global manufacturing footprint committed to safety, quality and efficiency, in support of an ever-evolving product line.

“GGB will have a noteworthy impact due to its size and scope, Roellgen said. They have capabilities and products new to our customers. We have the channel access to get them into new market spaces. From a customer value creation standpoint, it’s quite exciting.”

While GGB engineers specializes in polymer coatings, engineered plastics, fiber-reinforced composites and bimetals, Timken has long specialized in material science and tribology related to steel-made bearings. Dr. Carl Hager, internationally recognized Timken tribology specialist, explains.

Last Updated: 2023/11/20

Published: 2023/01/20