The Challenge

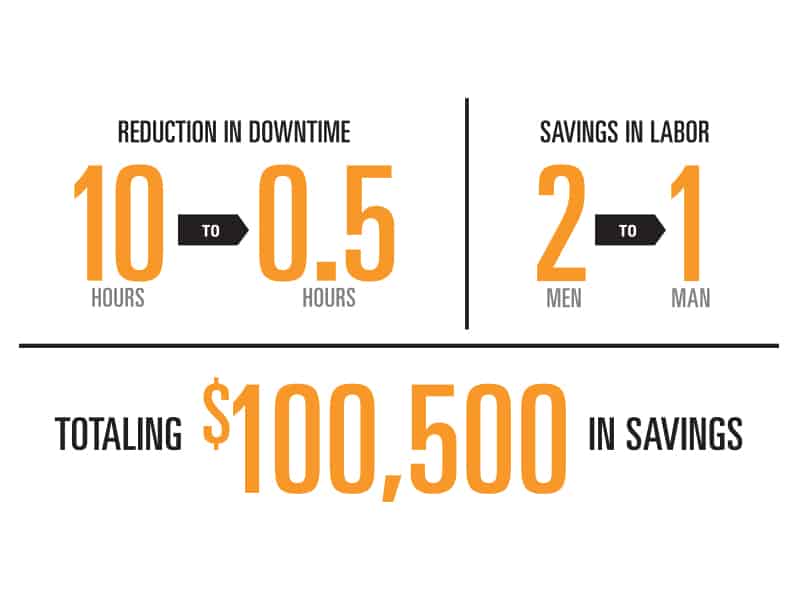

Facing high downtime costs associated with ongoing maintenance and labor needs in a demanding application, a Texas-based mining company sought the help of Timken in delivering an alternative solution.

The Solution

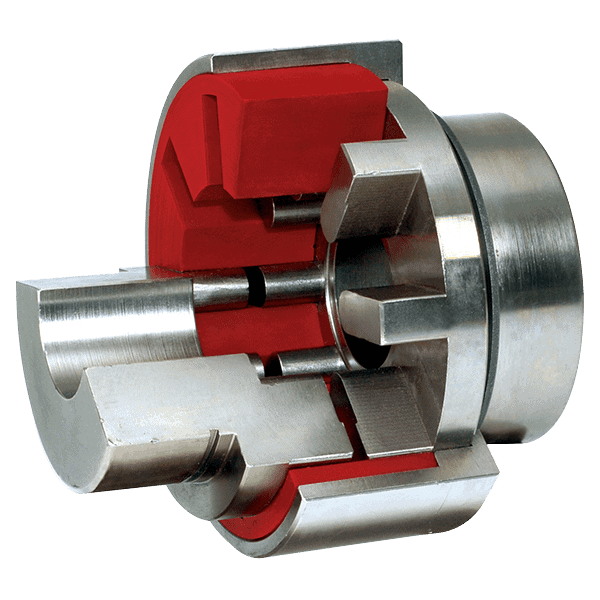

Timken identified its Quick-Flex® coupling to reduce labor and maintenance requirements. Additionally, with no metal-on-metal contact within the Quick-Flex Couplings, the need for grease lubrication and quarterly preventative maintenance attention was eliminated. Downtime was reduced to cove removal and insert placement.