Talent

Driven by Precision, Focused on Community

In Keene, N.H., Timken employees manufacture some of the world’s most precise bearings and sensor products to enable safe and efficient flight, space exploration, global communication and medical procedures. Their attention to detail carries over into how they care for their local community. Marcus Owens, plant manager, explains.

Influencing industry with diverse precision products

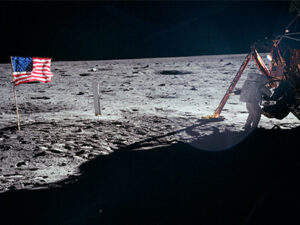

A typical day at the Timken facility in Keene, N.H., is anything but typical. Marcus Owens’ team may check the progress of a precision aerospace gimbal assembly order that requires U.S. security clearance, inspect unique bearing products to launch future space missions and manufacture sensors used in medical imaging equipment.

While much of the facility’s focus is on solutions that enable defense and commercial aviation, its products increasingly enable other essential industries that drive the world forward.

Its micro-precision bearings — often tiny enough to fit on the tip of a finger —are crucial in helping the constrained semiconductor industry produce chips used in everything from smart phones to satellites. Timken® magnetic encoders, a sensor solution produced at the facility, also support chip manufacturing and robotic warehouse technology like autonomous guided vehicles.

Its micro-precision bearings — often tiny enough to fit on the tip of a finger —are crucial in helping the constrained semiconductor industry produce chips used in everything from smart phones to satellites. Timken® magnetic encoders, a sensor solution produced at the facility, also support chip manufacturing and robotic warehouse technology like autonomous guided vehicles.

“We are unique in the Timken global footprint for manufacturing both engineered bearings and industrial motion solutions under one roof,” Owens said. “It gives our employees a lot of exposure to different markets, manufacturing processes and opportunities to contribute.”

Solving challenges to operate sustainably

Timken team members balance sustainable and efficient manufacturing with Timken customers’ ultra-high precision requirements through innovative problem solving.

James Thompson, manufacturing engineer at the Keene facility, said engineering and production teams collaborate to continuously improve processes everywhere they can. The results increase the speed at which customers take delivery of the Timken products, and often enhance the facility’s environmental sustainability.

For instance, Thompson was integral in restructuring portions of a shop floor assembly process that significantly improves the speed of product delivery to customers.

Along with other engineers and manufacturing employees, he reimagined a production line to do multiple steps consecutively so an order could be finished without any idle time in between steps. This reduced average lead times from 14 days to a single shift for a 500-piece order.

But one of his favorite problem-solving projects also happened to be one of his first, when he joined the company 12 years ago.

Thompson worked with other engineers to reduce the amount of lubrication used in Keene’s final bearing products. The proprietary solution retained the same bearing performance while reducing the facility’s lubrication waste.

“Getting that first big win was fun,” Thompson says. “But it was also significant.”

Putting community first

In Keene, 80 percent of employees volunteer and/or donate to more than 60 local charities. Several associates sit on local boards that advance community access to education, healthcare and necessities.

Ashley Beppel, quality manager, is the board vice president with Rise for Baby and Family, a non-profit that supports families with young children who have or are at risk for disabilities and developmental delays. Rise for Baby and Family is an early intervention resource and advocate serving more than 250 children annually.

“Play-based therapy is provided at no cost for families struggling with lack of affordable childcare in the area,” Beppel said. “I understand how important these services are. My brother had developmental delays growing up, but my family didn’t have a resource like Rise.”

Ashley Beppel explains how and why she got involved with Rise to help children with developmental challenges in her community.

Ashley also leads the Keene facility’s community outreach committee, which organizes plant volunteerism and giving. Employees support their local United Way campaigns, have built ramps to improve accessibility of several local buildings and volunteered to serve hot, nutritious meals to those dealing with food insecurity.

“We’re pretty engrained and understand the big issues,” said Owens. “It helps us direct our giving in a very meaningful way. We know our presence as an employer and as neighbors matters in our community.”

Working at Keene

Marcus Owens

Plant Manager

Joined Timken: 2010

First manufacturing job: Sheet metal assembler for Bombardier jets

Our products are tiny but impact everyone’s lives. It’s why we have a strong sense of pride in the products we make. We equip weather satellites, so anyone that checks the forecast on their phone benefits from our technology.

Ashley Beppel

Quality Manager

Joined Timken: 2016

Community engagement: named a “2022 Trendsetter” by a Keene-area business journal for her work as a young professional engaged in the community

Most folks here get involved in improving the community. That part of our culture is pretty special. Getting involved helps you know more people, and those connections help people feel more fulfilled personally and professionally.

James Thompson

Manufacturing Engineering Manager

Joined Timken: 2011

Favorite Timken® super precision bearing application: International Space Station water reclamation system

Keene is unique for our applications, lower volumes and extreme precision requirements. We’ll have production orders for five bearings because they’re going to Mars. There’s no need for 100, but the few we do make must have bearing tolerances smaller than the width of a human hair.

Timken work matters globally and across industries. Learn how Timken enhances sustainability for commercial aviation and is helping advance wave power as a new renewable energy alternative.

Last Updated: 2023/10/19

Published: 2023/10/17