Sustainability

Sustainability: Good Business Practice

As the global community witnesses the worsening effects of climate change, more consumers are choosing products using sustainability standards.

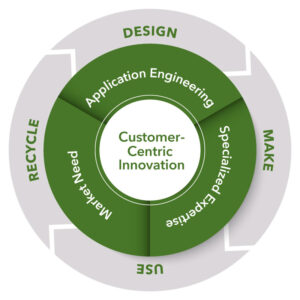

Application Engineering

- We develop customer-focused solutions for the next generation of the world’s most challenging problems and applications.

Market Need

- We innovate product and process technologies focused on changing market needs and emerging trends.

Specialized Expertise

- We are globally recognized for our specialized expertise in friction management, materials science and power transmission.

Timken’s Sustainable Engineering Process, outlined in its Corporate Social Responsibility (CSR) report, details the ways that Timken® products advance sustainability objectives for the company and its customers. Scott Hyde, senior scientist on Timken’s R&D team, helped describe and document what Timken has been doing for many years. He’s been working on efficiency for his entire 30-year Timken career — work that plays a significant role in today’s sustainability efforts.

Timken’s sustainability advantage

“The basic function of a bearing is to transfer motion in a way that reduces friction,” says Hyde. “We’ve improved on the original designs over the years, but at its core, a bearing is an inherently efficient product.”

Bearings are also made of steel — “the most recyclable material we have,” he says. “Most of the steel we purchase is from recycled scrap, and the majority of our bearings are 100% recyclable.”

The sustainability story doesn’t stop there, however. Over the years, Timken engineers have continued to optimize bearing design. Timken’s power-dense, fuel-efficient (PDFE) bearings provide one example, delivering more torque and power in a smaller volume to help vehicle manufacturers make the transition to electric vehicles.

Optimized Against Power Loss

Timken’s fuel-efficient bearings reduce power consumption up to 30 percent when compared to conventional bearings. Reducing power consumption in the bearings can also improve fuel efficiency as much as 2 percent.

Timken engineers constantly work to optimize bearings against power loss, delivering solutions that consistently exceed industry standards and customer expectations. Product sustainability work isn’t only about performance, however — it’s also about making installation and maintenance easier, reducing steps and requirements, and extending service life through calculations and predictive modeling techniques.

“We have a holistic approach to sustainability,” says Hyde. “Our products help customers reduce energy costs at every stage of the product lifecycle.”

“We’ve improved on the original designs over the years, but at its core, a bearing is an inherently efficient product.”

Scott Hyde

Senior Scientist, Timken R&D

The move to more efficient manufacturing

New processes make manufacturing more efficient, as well. In 2014, Timken facilities began installing alternative heat treat processes to its historical case carburizing process with more efficient, environmentally friendly through hardening processes. “With case carburizing, products might sit in a furnace upwards of a week to achieve their design strength requirements,” says Hyde. “Through-hardening techniques reduce furnace times considerably. In addition, Timken is using induction hardening processes, which enable on-demand heating technology.”

Made from Recycled Content

Timken’s uniquely designed tapered roller bearings for mainshaft applications help power wind turbines worldwide. The bearings are made of up to 100 percent recycled steel.

Those processes continue to be refined. “Today we also use austempering, which reduces product distortion so there’s less material input and waste,” he says. “While previous heat treatment required different part numbers to be processed separately, austempering allows us to combine different ring sizes together, so we can load furnaces more efficiently.”

Hyde is proud of the role he plays in making manufacturing more sustainable at Timken. “It can be challenging to engineer exactly the appropriate performance,” he says. “But with a century of expertise in materials science and metallurgy, Timken is equipped with the know-how to deliver safe, reliable bearings using more efficient processes.”

Good business practices are good for the planet

Timken sustainability efforts go well beyond bearings. Groeneveld-BEKA’s automatic lubrication systems, for example, reduce wasted grease and soil contamination, and teams around the world are implementing creative solutions to make Timken facilities more sustainable. The Groeneveld-BEKA facility in Wannberg, Germany, is already 100% powered by renewable energy sources.

It’s not only about social responsibility, either. As Timken drives down its carbon footprint, it also drives down costs for customers and the company. “Whatever we can do to save energy, that’s also good for the business,” says Hyde. “As we build more efficient, sustainable processes, we become a better, stronger company.”

Today, renewable energy is Timken’s largest end-market sector. See how Groeneveld-BEKA products help wind energy grow.

Published: 2023/08/3

“We’ve improved on the original designs over the years, but at its core, a bearing is an inherently efficient product.”

“We’ve improved on the original designs over the years, but at its core, a bearing is an inherently efficient product.”