Sustainability

EV Bearing Future Built on 120 Years of Timken Innovation

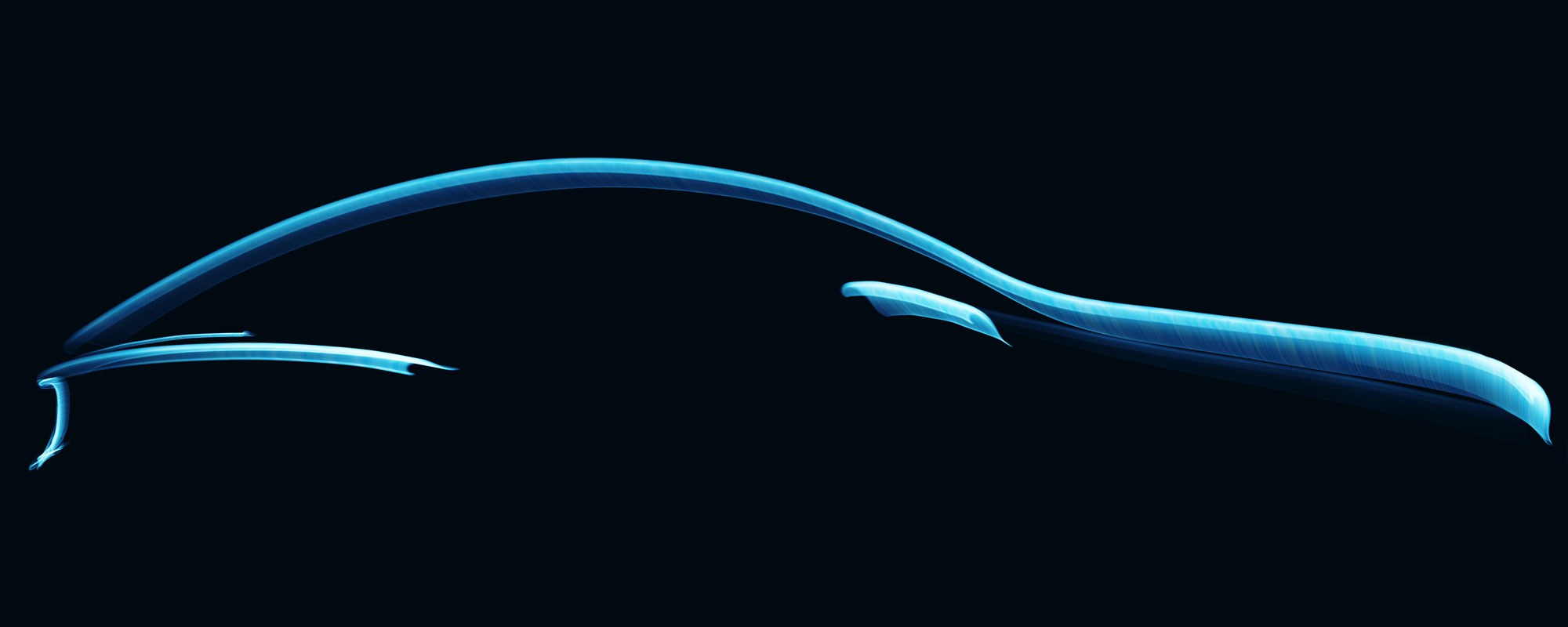

Early automakers relied on Timken solutions to help cars operate more efficiently. While gas-powered vehicles dominated the last century, today’s electric vehicle (EV) manufacturers are reimagining the automobile for sustainability and performance. Timken innovates next generation eDrive bearings for these novel vehicles—including the world’s longest-range electric luxury car.

“Great innovations address emerging trends and changing customer needs. A hundred years ago, mobility was the key driver for innovative design,” says Mike Marcelli, Timken sales director responsible for light vehicle electrification. “Now, it’s sustainability. We ask different questions than the engineers who came before us, but we still approach innovation by solving for the problem and delivering the performance we promise.”

“It’s not just what we make, it’s what we know. Timken performs at our best when there are technical hurdles to overcome, and that’s definitely happening now as automotive transforms to support a more sustainable world.”

Mike Marcelli

Timken sales director

Collective R&D knowledge helps EV bearing solutions take flight

Timken is currently working with EV manufacturers on several different bearing application projects, each with varying development cycles. EV propulsion systems commonly use charged batteries to power high-efficiency electric motors. Manufacturers diverge, however, in how they choose to transmit that power to the wheels. Those choices impact bearing design for new electrical powertrains, or eDrives.

Timken can technically support any eDrive scenario due to the company’s extensive R&D and engineering expertise across industries. Recently, company engineers applied industrial planetary gear drive knowledge to develop a bearing solution for one of the world’s longest-range battery-electric, high-performance luxury sedans.

“The project is unique because of the way power is transmitted to each of the wheels,” he says. “The results are a full-size sedan that performs like a supercar without using any fuel.”

Timken engineers work extensively with industrial customers using solutions from aerospace, agriculture, machine tools and robotics. They drew on these experiences to recommend power dense, fuel-efficient (PDFE) bearings suitable for the application. Following testing, bearings were redesigned to strengthen cage performance and provide greater protection against stress fractures.

Due to the high-speed requirements for the components, Timken R&D specialists have been performing bearing tests using aerospace lab equipment to develop new solutions for eDrive bearings.

“Conventional automotive engines run up to 7,000 rotations per minute (RPMs),” Marcelli says. “EV electric motors run closer to 20,000 RPMs. Our aerospace capabilities are crucial in supporting the automotive industry’s evolution toward all-electric technology.”

Innovating at the intersection of capability and opportunity

Timken strategically invests in R&D that complements the company’s existing capabilities while reflecting real-world market needs and opportunities. Currently, that sweet spot is in the electrification of full-size sedans, pickup trucks and SUVs as well as delivery vehicles that run daily routes and return to a charging station each night.

Industry projections suggest battery-powered electric cars will account for 30% of new car sales by 2030, and more than half of all light truck, van and SUV models will be fully-electric by then, too.

“Those are spaces that play to our strengths as the leading tapered roller bearing innovator, because they have tough requirements,” Marcelli adds.

Whether collaborating with a traditional automaker or an EV startup on an EV launch, Timken offers the same value: strong development partnerships and solutions that reduce weight, maximize energy efficiency and get vehicles to market on time.

Yet there are additional advantages for startups. From a technical standpoint, Timken has extensive R&D capabilities and knowledge in disciplines startups may not have access to elsewhere. Examples include prediction modeling, rheology and tribology.

From a process standpoint, Timken experts know what it takes to move a new vehicle into production and can offer those insights to startups looking to launch disruptive technology. They’ve had a front-row seat to new car launches for 120 years. Marcelli has been involved over 30 years.

“It’s not just what we make, it’s what we know,” Marcelli says. “Timken performs at our best when there are technical hurdles to overcome, and that’s definitely happening now as automotive transforms to support a more sustainable world. Electrification is the industry’s biggest shift in generations, and certainly during my career. It’s a shift where Timken is adding a lot of value.”

Timken optimizes sustainability and performance in many essential industries. Learn how Timken technology helps boat designers electrify workboats and supports aerospace customer demands for conserving energy, costs and the environment.

Last Updated: 2022/09/12

Published: 2022/08/14