Growth

Timken Adds Precision Gearing Solutions to Its Growing Portfolio

In 2011, Carl Rapp was on the receiving end of an acquisition when his company, Philadelphia Gear, was acquired by Timken.

“Timken is smart about integrations,” he says. “Company leaders make sure acquisitions don’t lose what makes them unique — retaining brands, headquarters, and great cultures of excellence.” Today, Rapp leads a group of Timken businesses that manufacture and repair gear drives, motors, and a variety of other industrial drive train components.

In the series of acquisitions that followed Philadelphia Gear, Timken added leading power transmission brands such as Drives, Carlisle Belts, Lovejoy and Groeneveld to its portfolio. Couplings, belts, chains, automated lubrication systems, linear motion products and much more now complement Timken’s roller bearing product line, for which the company has been known for 120 years.

This growth strategy set the company up to deliver an expanded portfolio of premium-quality brands to customers and distributors, along with the deep technical knowledge and market insights that they bring to the table.

“Timken is becoming a leading power transmission products and services company. We’ve proven ourselves as a preeminent roller bearing company. Now, we’re taking that foundation of quality, engineering expertise, and manufacturing excellence and building a larger, profitable network of brands and capabilities.” Carl Rapp, group vice president

In his role, Rapp is a key figure in Timken’s drive toward expanding its product line. In 2018, he was charged with leading the integration and growth of one of Timken’s newest acquisitions, Cone Drive. It was a full-circle assignment, given his background with the company.

A leader in precision motion control

Cone Drive has a proud history. Samuel I. Cone’s 1925 invention of the double-enveloping worm gear played a large role in U.S. military equipment during the 1940s. Its unique design increases the contact surface between the drive and the gearbox, which enables the load to be concentrated in a smaller space. This allows manufacturers to transmit more power in smaller footprints.

In 1950, the company’s current headquarters was established in Traverse City, Michigan. Cone Drive engineers began incorporating numerical control into its products, a technology that Traverse City resident John Parsons had invented in 1948.

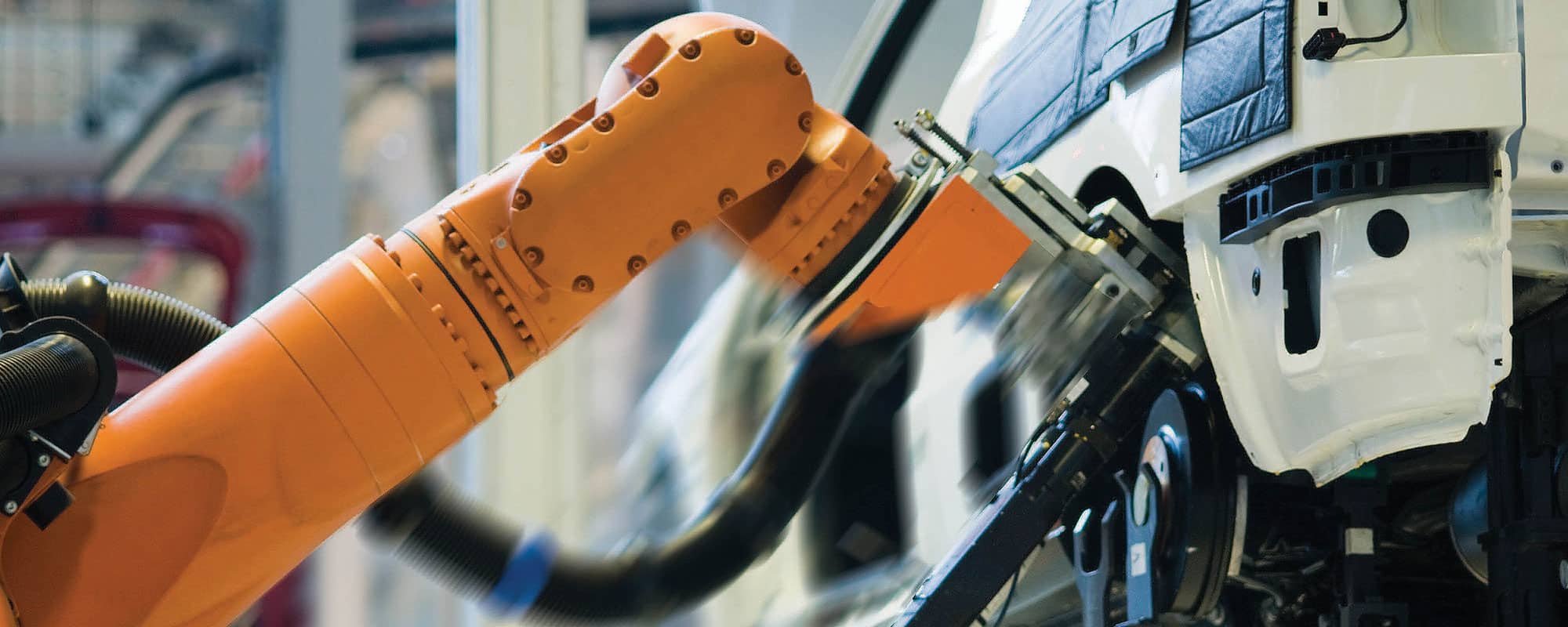

That innovation put the company on the precision drive path. While all Timken gearing solutions fit into the “premium” category, Cone Drive’s worm drive technology takes precision to the next level, with solutions for smaller equipment that require exacting standards for movement. Today, Cone Drive is known for its leadership in modern automation, producing gear sets for trackers that position solar panels as they follow the sun, for example, or for the robotic arms used in modern factories.

Expanding Timken’s global offerings

Cone Drive’s focus on growth markets such as solar, robotics, and food and beverage, complements existing Timken power transmission product lines, such as those sold by Philadelphia Gear. The acquisition represents a significant opportunity for Cone Drive customers, as well as for original equipment manufacturers (OEMs) who currently use Philadelphia Gear products.

Many Timken bearing customers also stand to benefit as the company begins offering Cone Drive products through its sales and distribution network, which covers North and South America, Europe, the Middle East and Africa. Today, Timken’s global presence makes purchasing a stainless-steel gear drive from Cone Drive as easy as ordering a standard bearing.

“Their value proposition is very similar to Timken,” says Rapp. “Cone Drive offers great adjacency for customers in terms of technology and product offerings, especially in industries and applications where precision equipment requires worm gear drive technology.”

The benefits don’t stop there. Cone Drive acquired China-based slewing drive manufacturer, H-Fang, in 2014. “Much of the new investment in the world’s most advanced machine tools is happening in Southeast Asia,” says Rapp. “H-Fang gives us a presence there for those customers and a competitive position within those product lines.”

Like Timken, Cone Drive offers OEM equipment parts, along with aftermarket servicing of an installed base of equipment. With this acquisition, Timken continues its strategy of offering adjacent products and services that complement its core offerings, with equal quality and superior brand recognition.

The strategy offers customers the advantage of OEM and aftermarket services that have entire systems in view, rather than only one small part. “We’re taking advantage of the trust our customers have placed in us to selectively add companies and services that help expand our revenue base and solve more customer problems,” says Rapp.

Hear more about how the Timken acquisition strategy makes the company better, not just bigger.

Last Updated: 2021/08/19

Published: 2018/11/5