The Challenge

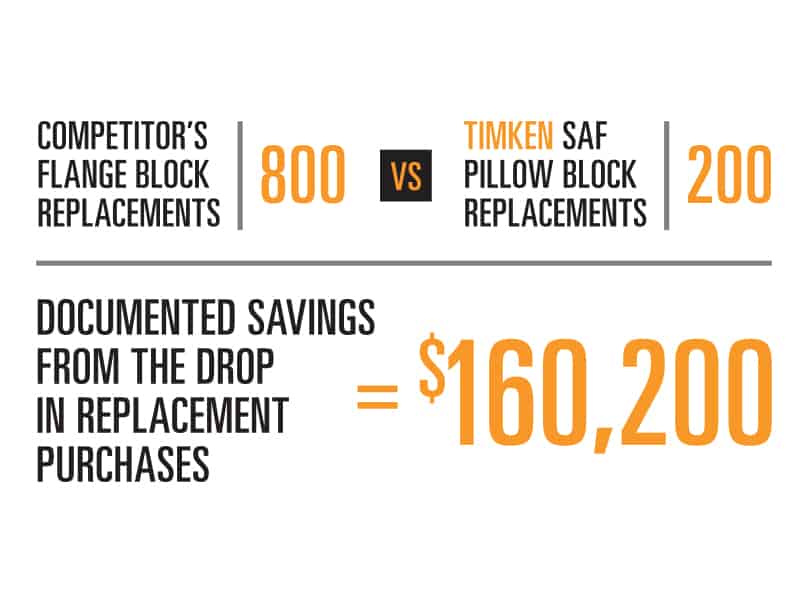

A steel products producer was challenged with limited flange block bearing life in its hot roll transfer line. Requiring replacement four times annually, the company sought an alternative solution to eliminate replacement and downtime costs.

The Solution

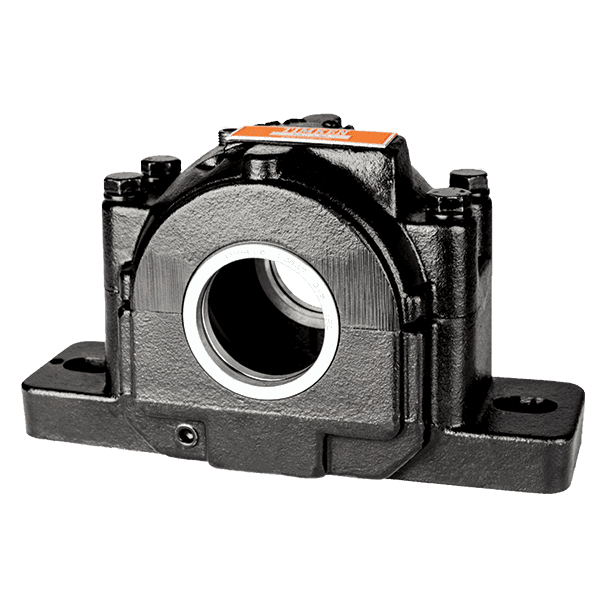

The Timken engineering team analyzed the specific operating conditions of the application and identified the need for more robust protection. The team proposed steel SAF split pillow blocks, along with supplementary high-temperature lubricant and end covers to extend each bearing’s life to a full year.