Case Study

Solar Power: Mohave Desert, California

The Project:

Ivanpah Solar Electric Generating System

Mohave Desert, California

In 2013, a 377-megawatt concentrating solar power (CSP) complex came online in California’s Mohave desert. The Ivanpah Solar Electric Generating System comprises three fields of heliostat mirror panels covering 3,500 acres. Each heliostat focuses the light of the sun onto one of three receiver towers, which use that concentrated sunlight as the primary power source for steam turbines that generate electricity for 140,000 California homes.

The Challenges

CSP works a bit like trying to start a small fire with a mirror or a magnifying glass. If you aren’t holding the mirror so that it catches the sun — no fire. Likewise, if you can’t align the concentrated sunlight steadily and precisely at a combustible target — no fire.

To optimize plant production, Ivanpah engineers had to align 173,000 heliostats in such a way that they reflect maximum sunlight toward the receiving towers, at all hours of the day. To accomplish that feat, they faced three big challenges:

#1: The position of the sun changes constantly. Each heliostat needs to rotate up to 270 degrees each day at speeds as slow as 0.009 rpm. The more accurately the heliostats can focus the sun’s rays, the higher the plant’s output.

#2: Desert winds can gust up to 190 miles per hour. Ivanpah’s heliostats measure 25 square meters or more across. In the expanse of the Mohave, those large, flat panels can act like sails during a windstorm, creating instability and backlash in their positioning gears. In addition, the gears must stand up to constant sand and debris carried by the wind.

#3: Maintaining 173,000 heliostats could be cost prohibitive. Once it starts, gear backlash feeds on itself and can wear down a gear set quickly. To keep energy costs low, Ivanpah’s heliostat gears must maintain their stability and precision for decades at a time.

The Solution:

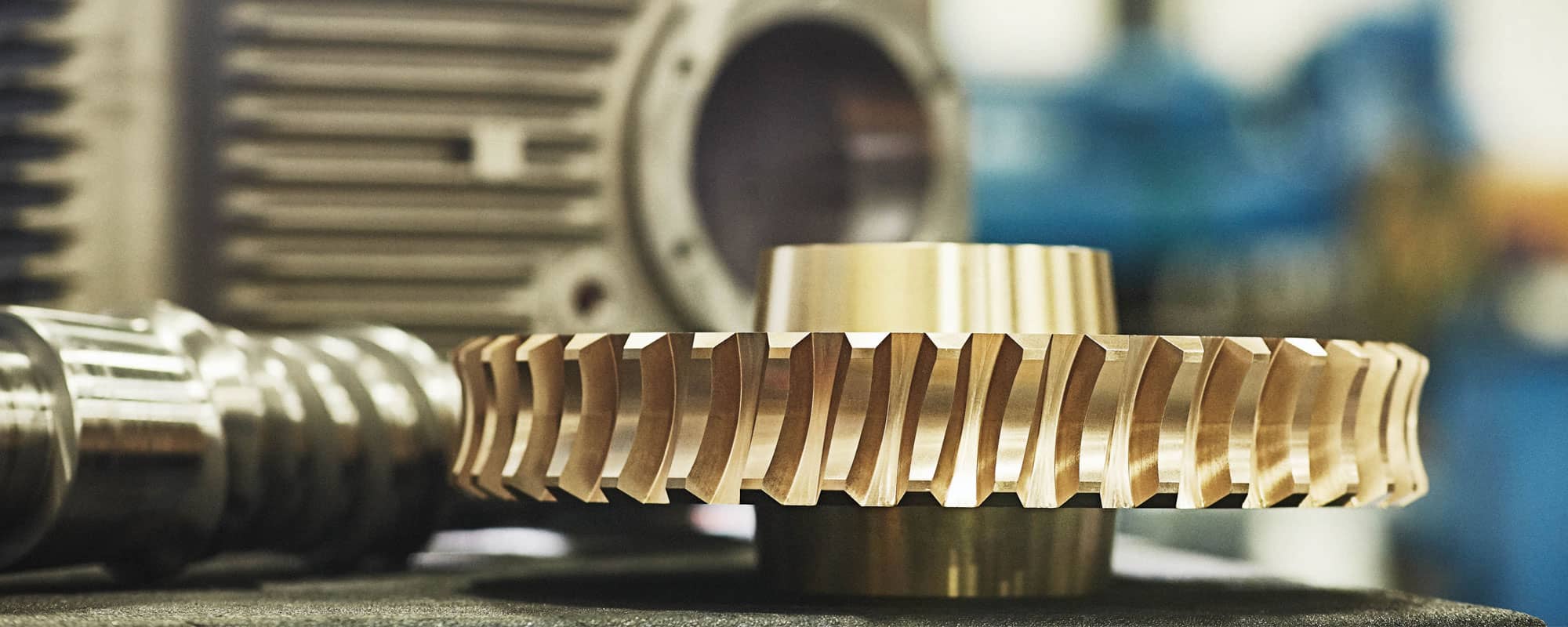

Double-enveloping worm drives from Cone Drive

After evaluating gear tracking drive systems from several manufacturers, BrightSource decided to install double-enveloping worm drives from Cone Drive in tens of thousands of Ivanpah heliostats. The drives provide the kind of high-precision motion control used for satellite positioning and surgical tools and are designed to reach up to a 35-year lifespan.

How it works

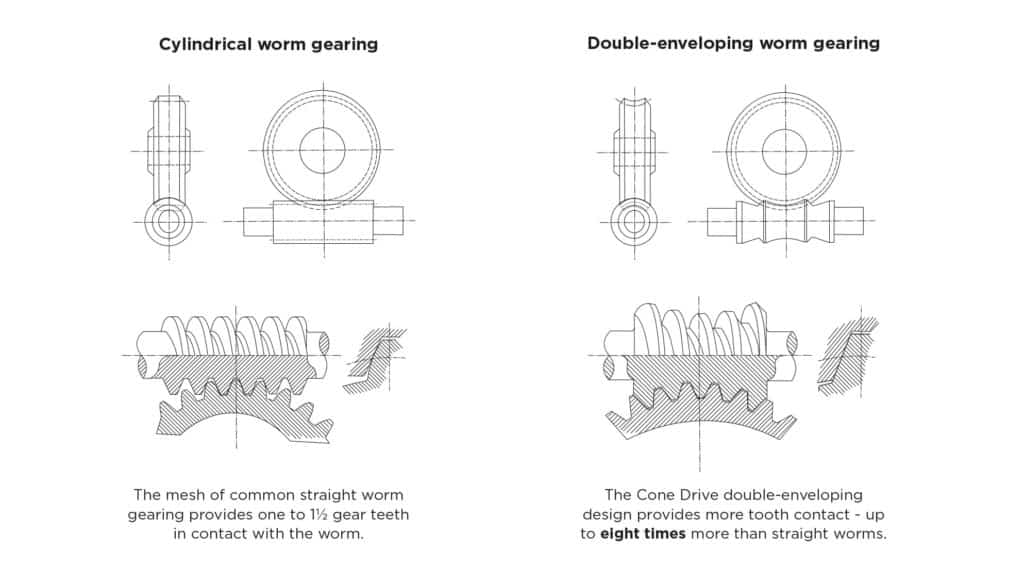

Cone Drive’s double-enveloping worm drive increases the contact area between the gear and the worm, to offer more stability than a traditional worm drive. The hourglass shape of the worm screw wraps around the gear, which also wraps around the worm.

“This superior mesh contact translates to higher torque capacity and greater shock load resistance,” says Jacob Randall, director of strategic markets at Cone Drive. “Double-enveloping gear sets help maintain zero backlash integrity, eliminating any clearance or lost motion caused by gaps between the teeth and the thread.”

Cone Drive’s double-enveloping worm drive increases the contact area between the gear and the worm to offer more stability than a traditional worm drive.

The Benefits

#1: Precision. “The precision we can achieve with double-enveloping was a great fit for Ivanpah,” says Randall. Cone Drive gear sets make it possible for Ivanpah heliostats to concentrate more sunlight on receiver towers more reliably. When you have 173,000 heliostats, even small improvements in accuracy can make a big difference in plant output.

#2: Stability. Cone Drive’s double-enveloping worm drives help keep Ivanpah heliostats working at optimum levels, even during extreme wind conditions. “Torsionally, the gear is extremely stiff,” says Randall. “When the wind catches a mirror, that mirror doesn’t move.”

#3: Zero maintenance. Because the heliostats are so stable, the Cone Drive solution keeps gear backlash to a minimum, along with wear and the need for expensive repairs. The gears are lubricated internally and sealed for life, to resist sand, dirt and debris, and eliminate maintenance tasks.

The Results

Over the past seven years of operation, the Ivanpah team has successfully increased the plant’s output of clean energy, relative to the amount of natural gas it uses to keep steam turbines operating when the sun is not in the sky or is hidden by clouds.

- Since 2015, the plant has averaged nearly 700,000 megawatt hours of solar energy per year.

- Ivanpah serves 140,000+ California homes during peak hours of the day.

- The plant is on track to avoid 13 million tons of carbon dioxide emissions over its 30-year lifespan.

As a result of their success with Cone Drive’s Ivanpah solution, BrightSource Energy is using Cone Drive technology for other CSP projects, including one 700-megawatt plant in the United Arab Emirates and another in Israel’s Negev desert.

“Solar power technology continues to improve,” says Randall. “Small, incremental improvements can add up to tremendous gains amid soaring interest in renewable energy sources.”

Read more about Cone Drive’s double-enveloping worm gear and participation in the solar industry.

Last Updated: 2021/08/19

Published: 2020/10/29