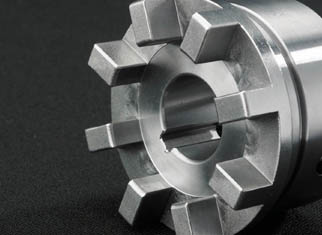

Timken Quick-Flex® elastomeric couplings are durable enough to face the challenges of harsh environments, yet need minimal maintenance. They are easy to install and require no lubrication.

Timken Quick-Flex couplings operate without any metal-to-metal contact. Because the metal hubs don’t wear, the elastomeric insert is the only spare part you’ll need. For especially harsh environments, such as food processing, we offer a stainless-steel version of each coupling.

You may choose from multiple cover and insert configurations that are able to withstand some of the most extreme environments.

Solutions for your needs:

- Replaces virtually all styles of couplings in high- and low-torque applications for plant standardization.

- Solid and split covers handle higher speeds and increased torque.

- Design dampens transmitted torsional vibration and shock to help extend the life of the coupling and surrounding components.

- Couplings accept misalignment, up to 2 degrees.

- Timken inserts reduce downtime and replacement costs because inserts can be replaced without moving or disassembling the driving or driven equipment.

- Great for inventory reduction because the only spare part required is a urethane insert that can be replaced in just a few minutes.

Applications:

- Motor to gearbox. (Low torque/high speed)

- Gearbox to driven equipment. (High torque/low speed)

- Motors to pumps.

- Any drive shaft to a driven shaft.

![[Page Title]](https://www.timken.com/wp-content/uploads/2016/07/MechanicalPower_Couplings.jpg)