The Challenge

Blender truck augers combine sand and chemicals using spherical roller bearing housed units in the hydraulic fracturing process. Insufficient seals allow contaminants to seep inside the bearing housings. This seriously damages the bearings and disrupts drilling operations.

The Solution

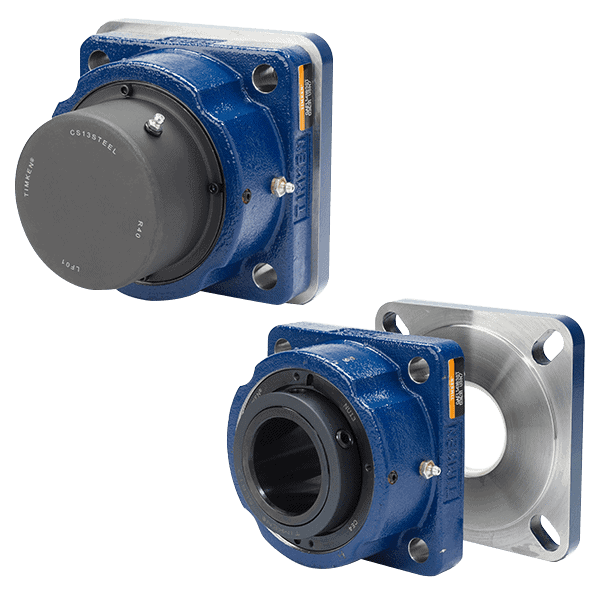

A combination of Timken® four-bolt flange bearing with triple lip urethane seals, as well as secondary seals came to the rescue. Added to the sealed unit is a steel backing plate with a labyrinth Dupont™ Teflon® seal that sits on the shaft and turns with it. A bolt-on steel cover was added to the front of the bearing. The steel covers are accepted by all standard flanged bearing units. The combination of the steel cover and added seals helped to greatly decrease ingress of contamination into the bearing.