The Challenge

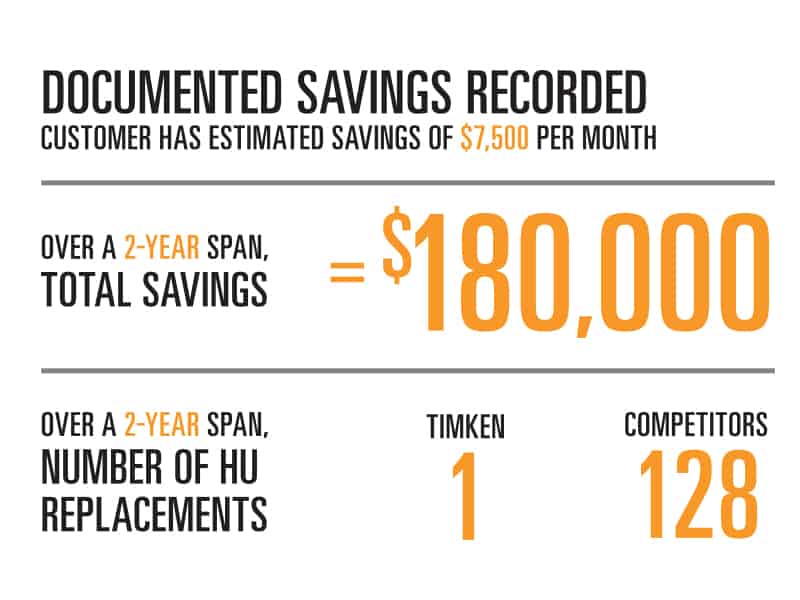

A Pennsylvania steel company faced limited bearing performance and high replacement rates with housed units on its rail mill application. Units required replacement at a rate of four per month, resulting from housing breakage that would occasionally cause equipment jamming.

The Solution

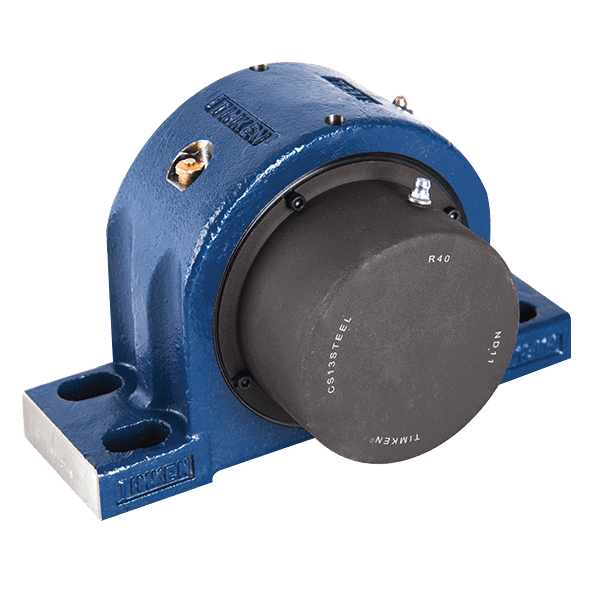

Timken proposed the use of its rugged spherical roller bearing solid-block housed units to stand up to the demanding application. Upon installation, the Timken solution delivered outstanding durability and two full years of performance before requiring replacement—the same time in which 128 competitive bearings would have already failed.