The Challenge

A tricky installation process regularly led to bearing damage and compromised performance for a busy lumber mill in Idaho. The costly competitor’s ball housed units created a drag on profitability and productivity across the operation, leading the customer to need a more cost-effective and high-performing solution.

The Solution

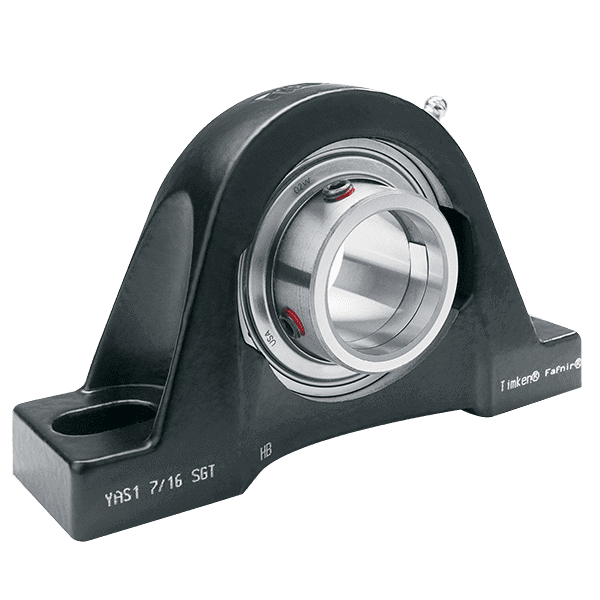

The Timken® Fafnir® ball housed unit with shaft guarding technology (SGT) proved ideal for applications throughout the mill. Installing the same way as a standard setscrew bearing, operators enjoyed a simplified installation process. The Timken unit’s stainless steel SGT ring construction also helps prevent shaft damage during installation and operation for improved overall performance.