We engineer our commercial vehicle wheel end accessories and tools to help increase the reliability and efficiency of fleet operations.

Accessories

Die-Cast Aluminum Hub Caps- Durable and cost-effective.

- OEM approved with a precise fit and long, low maintenance service life.

- Oil bath types may include a side fill plug.

- Machine-applied window for a secure seal and easy oil level checks.

- Vented fill plugs maintain low internal pressure caused by normal heat buildup.

- Hubodometer versions available for most applications.

- Durable and cost-effective.

- OEM approved with a precise fit and long, low maintenance service life.

- Oil bath and grease types available.

- Powder-coat painted finish (available with duplex nickel-plated and chrome-plated finish).

- Machine-applied window remains clear and shatter proof.

- All units are corrosion-resistant.

- Durable and cost-effective.

- OEM approved with a precise fit and long, low maintenance service life.

- Threaded units available in die-cast aluminum or full plastic (oil bath and grease types), or a hubodometer version.

- Standard or chrome finish, with or without side fill or vented plug.

- Durable and cost-effective.

- OEM approved with a precise fit and long, low maintenance service life.

- Replacement hub caps for PSI-equipped wheel ends.

- Helps simplify record keeping, reduce inventory and improve scheduling of regular maintenance and safety checks (follow OEM recommendations for mileage between service intervals).

- Extremely durable: UV protected polycarbonate material is hermetically sealed for a moisture-proof, tamper-proof, air-tight seal and the zinc protected housing is corrosion-resistant.

- Available in miles or kilometers (pre-set units available upon request).

- Available in a full range of ratios that meet the latest tire manufacturer’s specifications.

- Accurately records revolutions in both directions (either side of the vehicle) – even on tough road conditions.

- Individually serial numbered for easy tracking.

- Easy installation – no wiring, power or complicated programming required; mounts with a standard ½”-20 mounting stud.

- Supported by a full line of mounting brackets and hubcaps.

- Operating temperature range: -40° F to 180° F (-40° C to 85° C); Product mass: 1.35 lbs. (600 grams).

- One model fits any tire application.

- Programmable in miles or kilometers with ability to preset mileage (programming tool and easy-to-follow instructions included).

- Secure lockout feature with ability to permanently disable changes to the unit’s set-up.

- Separate trip and lifetime totals.

- Eliminates expensive calibration machines, readers and complexity.

- Durable construction: die-cast zinc case, oil impregnated bronze bearings, hardened steel shaft.

- Fully mechanical with Acetal resin gear, pinions and wheel.

- Unique counter balance design eliminates orbiting and provides precision accuracy.

- No calibration, tampering or batteries.

- Reduces installation, maintenance and inventory carrying costs.

- Fast and accurate method of securing and adjusting wheel end components (within the recommended setting range).

- Helps extend seal and bearing life and tire tread.

- Eliminates three-piece adjusting nut systems (jamming style) and two piece systems that require locking keepers.

- Easy installation with a six-point socket and torque wrench.

- Available for trailer, drive and steer axles for standard or “D” flat slotted spindles.

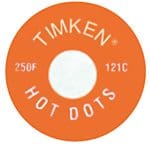

- Easy visual indicator – changes from white to black when wheel end temperature exceeds 250° F (121° C) – accurate to within +/-1°.

- Simplifies pre-trip wheel end inspection and verification; helps reduce unexpected repairs.

- Strong adhesion even in wet conditions -40° F to 300° F (-40° C to 148° C).

Installation and Adjustment Tools

We also offer a variety of installation and adjustment tools designed to make it easier to accurately install and adjust bearings and seals. Clean-Up Wheel (for wheel end preparation)

- Part No: HACT1

- Saves time: Quick and easy to use to accurately verify wheel end play.

- Works anywhere: Adjustable positioning posts for all axle and hub models (including aluminum hubs); adjustable for truck or trailer wheel ends.

- Strong attachment: Industrial strength magnets ensure secure attachment.

- Part No: BADG1

- 494125: 12 TPI Trailer

- 493250: 16 TPI Trailer

- 492125: 18 TPI Steer

- 492125: 12 TPI Steer

- 494000: 12 TPI Drive

- Disposable tool packaged with seal.

- Ensures correct seal installation (improper installation causes most seal failures).

- Included with seals (part numbers ending in “T”).

- Drive handle, seal driver, bearing guide and hex nut included.

- Components available separately.

- Drive Handle Part No: H1.

- Seal Driver (reference application specific data).

- Bearing Guide (reference application specific data).

- Hex Nut (included with drive handle).

- Two separate tools required: Axle sleeve driver and drive plate.

- Components available separately.

- Axle Sleeve Driver Part No: AD1.

- Drive Plate (reference application specific data).

![[Page Title]](https://www.timken.com/wp-content/uploads/2017/07/wheel-hub-banner.jpg)